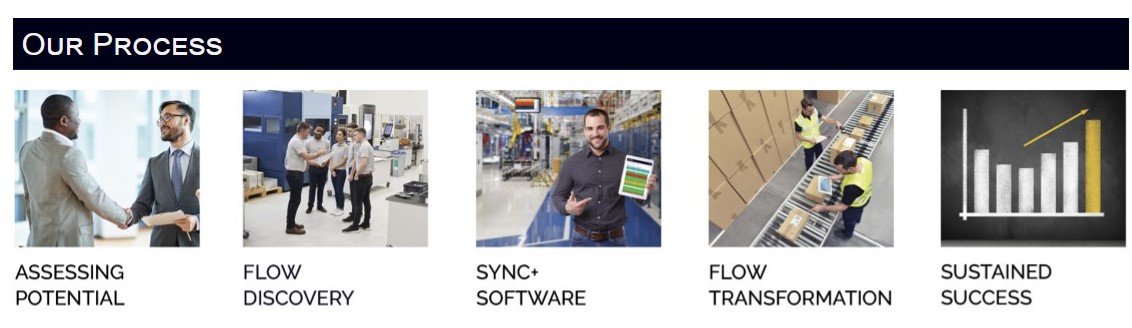

FLOW: Accomplish Continuous Improvement Process Through a Holistic Alignment of the SYSTEM flow. Efficiency of processes is not a goal which for many is counterintuitive.

Tactics: Use innovative TACTICS to include

- Control Point Theory

- Manufacturing Module

- Supply Chain Module

- Critical Chain for Project Flow

- Thinking Processes

- Throughput Accounting

Leadership: Empower your LEADERSHIP to identify opportunities for system improvement resulting in increased production, increased profits, reduced delivery time, and engaged, prosperous personnel

SYNC+™ Technology: Use our proven SYNC+™ TECHNOLOGY products to gain insights into hidden capacity, enable manufacturing process improvements, make astute engineering decisions, and enhance all planning to include sales and customer service. For more information about SYNC+™, click here

Why?

- To help you synchronize all areas for your business, based on current and unrealized production capacity.

How?

- Eliminating Efficiency Syndrome

- Eliminating Early Release

- Replacing Due Dates with Buffer Status

- Releasing work in synchronization with constraint

- Have Work priorities controlled by Buffer Status

- Focus on Flow not utilization of resources

Results?

- Organizations will grow more profits, more quickly, when they control the Flow in their system.

- Improving everything is not possible. Knowing what to change will improve Flow, Profits and ROI.

- Improves OTD/OTIF/Availability to near 99%

- Life for employees is better, calmer, more satisfying

- Increases capacity up to 35% with existing resources

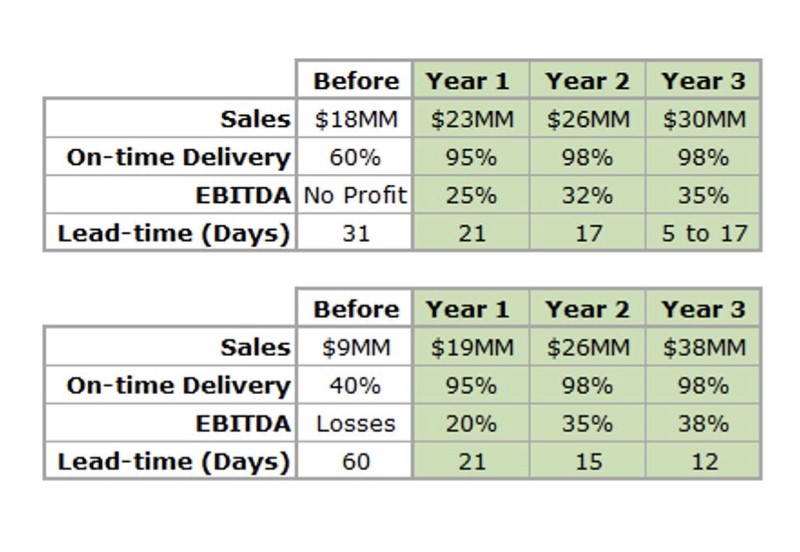

Flow Management creates fast results:

- 35% Increased Throughput

- 99%+ On Time Delivery

- 200% Higher Profitability

- 30%+ Increased Capacity with Existing Resources

- High Employee Morale and Retention

It gave us a lot of flexibility because it increased our ability to show a customer we could perform… Then our sales went up and just skyrocketed. We proved that if you perform, business will come. And from a sales and profit standpoint, we lived what is being promoted. After three years, our profit was equal to our sales the year prior to working with FlowTLS.

– VP Operations, Medical Device Manufacturer

Before we had the FlowTLS SYNC+ System, our on-time delivery was around 20% and our lead times were high. There was a lot of work in progress and everything had to be expedited. SYNC+ quickly eliminated the chaos and expediting in our plant and has drastically improved our On-Time Delivery and reduced our lead time. Everyone in the shop now knows their priorities from the SYNC+ Displays in their work areas.

– Shop Manager

As a planner it has allowed me to take control of the shop floor in a much more organized way. We no longer expedite. I can release work to the shop and set priorities using SYNC+. It works well with our ERP and has many enhancements to allow me to see the current load on the shop floor at key operations as well as out of stock conditions. SYNC+ also coordinates with the other parts of our factory to show when I can release work. It really works well.

– Planner

At first, I was skeptical that the new shop floor system, SYNC+ would do what it promised. Within a few days it lived up to its promises and coordinates all priorities in the shop. Work moves faster and we have a lot less work-in-progress.

– Shop Floor Machinist

The FlowTLS Process started with a process to create alignment with entire management team, so the implementation of SYNC+ would be in alignment with primary business goals and the implementation. SYNC+ has allowed us to get to 100% On-Time Delivery for over a year and dramatically improved our profitability. The Gain in profitability was quick and beyond anyone’s expectations.

– VP & General Manager

To learn more about the FlowTLS approach and start a conversation on how we can improve your business, please follow this link to the contact form.

Our plan is to:

- Schedule a shop visit

- 1 hour, discuss your system

- Book a free simulator session

- 3 hours, 5-12 people

- Book a free training session

- 60-90 minutes, 3-10 people

We will be discussing your bright future shortly!